Новое поступление

Spot Welder Portable 6 Gears Adjustable Mini Welding Machine for 18650 Battery Tool Kit | Инструменты

Aeromodelling DIY Portable 7-16V High Rate Lithium Battery Energy Storage PCB Circuit Board 8 Tube Current Spot Welde | Инструменты

Бесплатная доставка BT-300HHO промышленный HHO лучший сварочный аппарат для тонкой

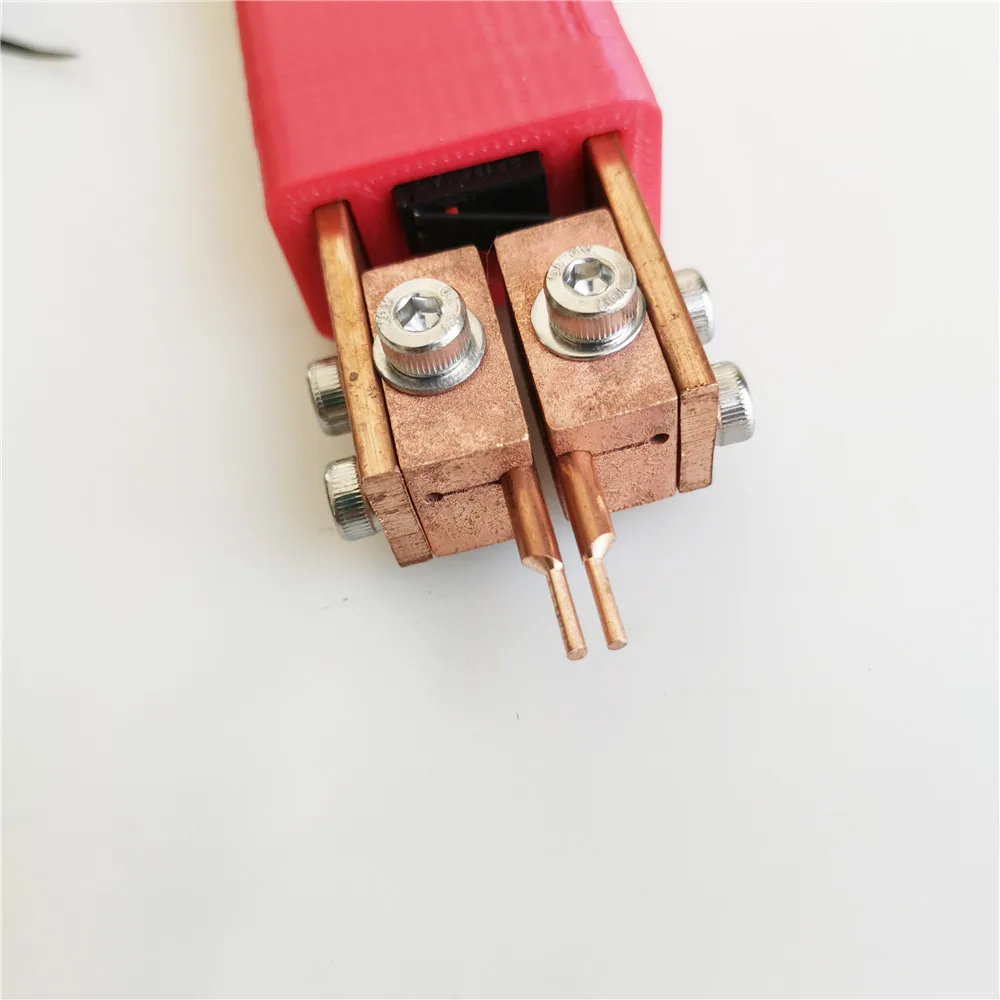

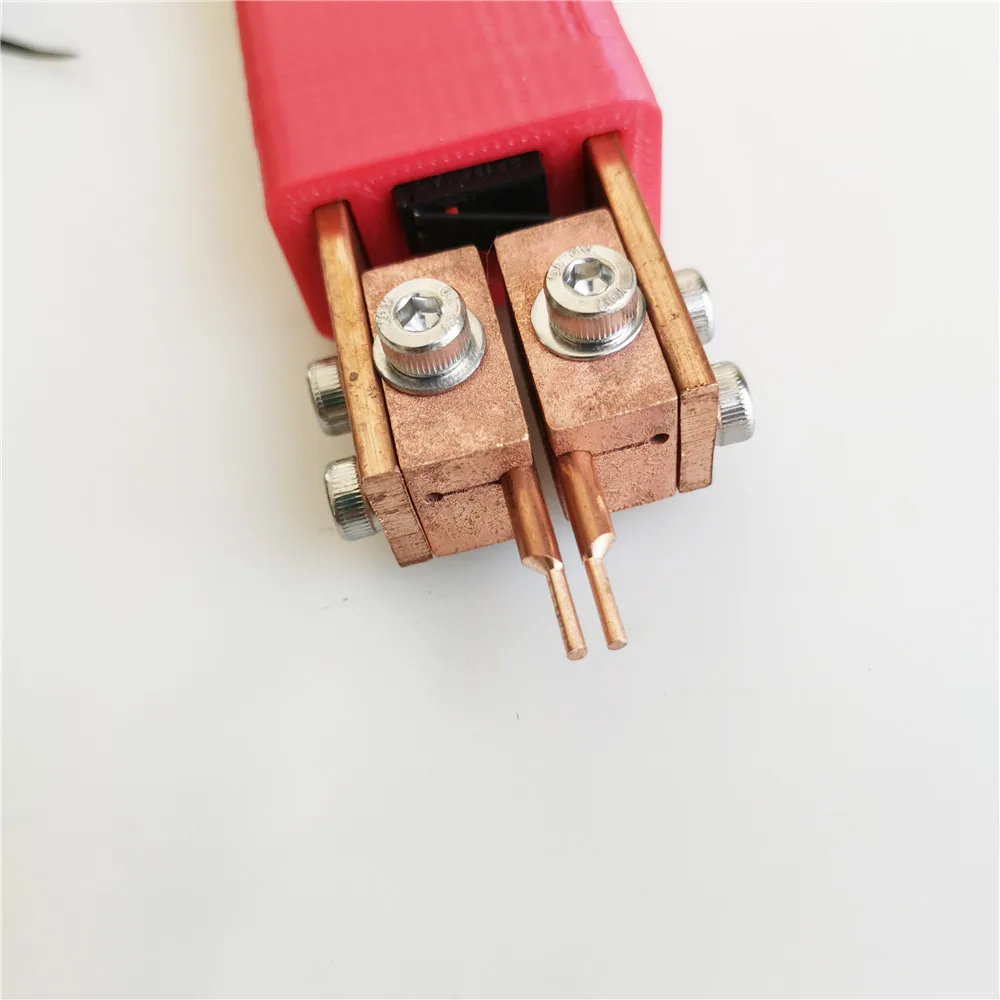

80mm Single/Dual Head Welding Feet Needle Alumina Copper Material Spot Pin welding accessories Welder | Инструменты

Портативный Аппарат для точечной сварки DIY аккумулятор 18650 различные сварочные

Комплект приводных роликовых колес для Mig Сварочная проволока 25 мм диаметр 0 8-0 9

Аппарат для точечной сварки сделай сам ручка с аккумулятором 18650 Автоматический

Brushless Motor Store

Магазина Brushless Motor Store работает с 01.04.2019. его рейтинг составлет 94.75 баллов из 100. В избранное добавили 2078 покупателя. Средний рейтинг торваров продавца 4.8 в продаже представленно 876 наименований товаров, успешно доставлено 7398 заказов. 3066 покупателей оставили отзывы о продавце.

Характеристики

3mm Aluminum oxide copper 8 pcs /set of welding tips as spare part for pen | Инструменты

История изменения цены

*Текущая стоимость 654,74 уже могла изменится. Что бы узнать актуальную цену и проверить наличие товара, нажмите "Добавить в корзину"

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-18-2025 | 778.63 руб. | 817.74 руб. | 797.5 руб. |

| Aug-18-2025 | 772.98 руб. | 811.7 руб. | 791.5 руб. |

| Jul-18-2025 | 647.70 руб. | 679.63 руб. | 663 руб. |

| Jun-18-2025 | 759.39 руб. | 797.7 руб. | 778 руб. |

| May-18-2025 | 661.95 руб. | 694.80 руб. | 677.5 руб. |

| Apr-18-2025 | 746.57 руб. | 783.81 руб. | 764.5 руб. |

| Mar-18-2025 | 739.49 руб. | 776.97 руб. | 757.5 руб. |

| Feb-18-2025 | 732.17 руб. | 769.95 руб. | 750.5 руб. |

| Jan-18-2025 | 726.27 руб. | 762.91 руб. | 744 руб. |

Описание товара

Brand Name : RERAS

Dimensions : /

Max. Welding Thickness : 3.0MM

Rated Duty Cycle : 100%

Usage : Nickel spot welding battery spot welding

Model Number : Alumina copper welding machine welding needle

Rated Capacity : /

Weight : 0.05kg

Model Number : Alumina copper welding machine welding needle

Rated Capacity : /

Rated Duty Cycle : 100%

Max. Welding Thickness : 3.0MM

Dimensions : /

Weight : 0.05kg

Usage : Nickel spot welding battery spot welding

model : SUNKKO

Scope of application : Nickel sheet spot welding battery spot welding

melting point : 90O

Core diameter : 1.5mm

Texture of material : Alumina copper

product name : Copper

Processing and customization : Is

Type : Alumina copper

Standard diameter : 3mm

Note: 1 set is 8 PCS

Main performance:

1) hardness & gt; 83HRB,

2) conductivity > 85IACS,

3) Softening temperature 900 C;

4) Dispersion hardening CuA12O3 composites have high strength, high hardness, high conductivity and high softening temperature.

5) In the United States, Japan and other countries have been widely used in large microwave tube structures and conductive materials, switching switches, silver contacts and spot welding electrodes, etc.. The material is produced through the Cu-Al alloy internal oxidation-isostatic embossed embryo-sintering-thermal extrusion-pulling-processing molding process. It has good thermal stability, good plasticity and processing performance. &; nbsp;

6. The supergroup corrosion resistance of galvanized steel sheet with resistance welding electrodes makes it widely used in more and more fields, but it also brings new problems to resistance welding technology. How to avoid yellowing of welding joints, virtual welding and zinc sticking of electrodes during welding process, which lead to the decline of product quality and low work efficiency, becomes more and more urgent. Dispersed Al-Cu alloy is undoubtedly the most important one. Ideal materials have excellent resistance to welding and arc burning for welded coated steel plate and nickel plate, which can improve the service life of electrodes, reduce the frequency of electrode dressing, and minimize the possibility of welding interruption and virtual welding. They are especially suitable for welding pure nickel strips and nickel-permeated steel sheets in the production of mobile phone batteries.

7). With the development and progress of the electronic industry, lead frame materials and electronic packaging materials, the lead material requirements of electronic components such as large-scale integrated circuits are getting higher and higher. The high temperature and rigidity of dispersion reinforced copper alloys will gradually replace traditional ferronickel alloys. material. &; nbsp;

Application: Suitable for spot welding between nickel strip, Nickelized steel sheet and coated steel strip in battery production. In the production of Ni-MH batteries, Ni-Cd batteries, polymer batteries, lithium batteries and other batteries, spot welding connectors, cores and lead-out sheets are used.

Main welding advantages: &; nbsp;

1. Avoid electrode sticking.

2. The welding site is not yellow, and the welding point is beautiful. &; nbsp;

3. Avoid the phenomenon of virtual welding.

4. Put an end to the phenomenon of welding spark is generated.

5. Excellent electrical conductivity and thermal conductivity. The

6. Good high temperature performance.

7. As to meet the requirements of SGS environmental protection standard requirements and MSDS.

Смотрите так же другие товары: